Jul.03.2024

Anodization Color Development Process Part I: Introduction and Case One - Creating an Anodized Color from a Pantone Target Reference

Part I: Introduction and Case One - Creating an Anodized Color from a Pantone Target Reference

Our expertise in anodizing techniques allows us to craft models using the process and develop tailored anodized colors based on provided target samples for use in subsequent model-making or for mass production purposes.

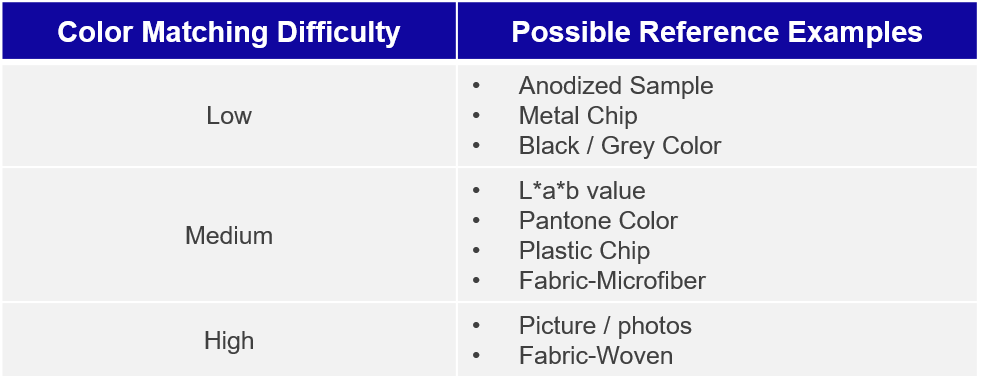

The level of intricacy in developing these anodized colors varies depending on the target samples we receive, which impacts both the development time and cost.

This newsletter will be split into two parts, with Part I below. Each part illustrates a case from our experiences in the anodized color development process. We hope this will provide a comprehensive insight into our anodized color development process and capabilities.

Case One: Creating an anodized color to match a Pantone color reference

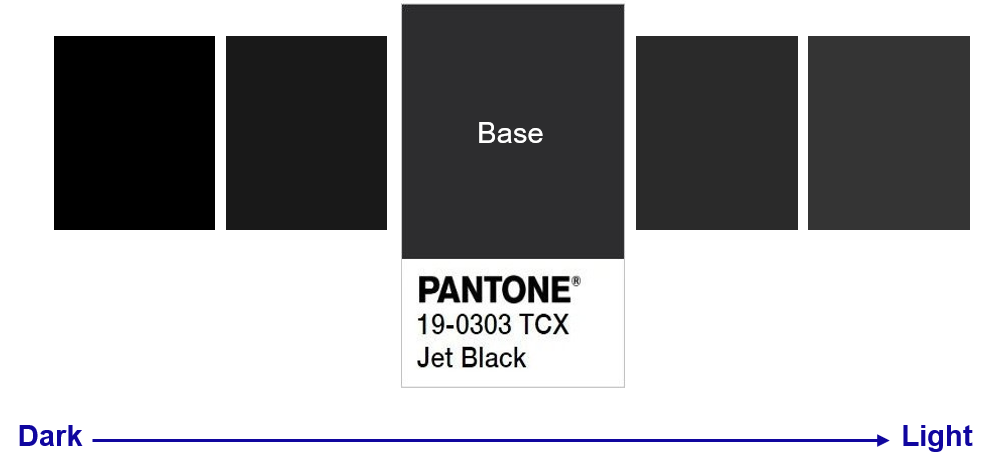

After receiving a deep black Pantone color swatch from our customer, we were requested to create anodized colors in both dark and light shades. However, our initial tests revealed that the warm-toned nature of the target Pantone color made it unfeasible to achieve a darker black with the warm-toned anodizing dyes. As a result, we could only develop anodized colors that were lighter than the Pantone color target.

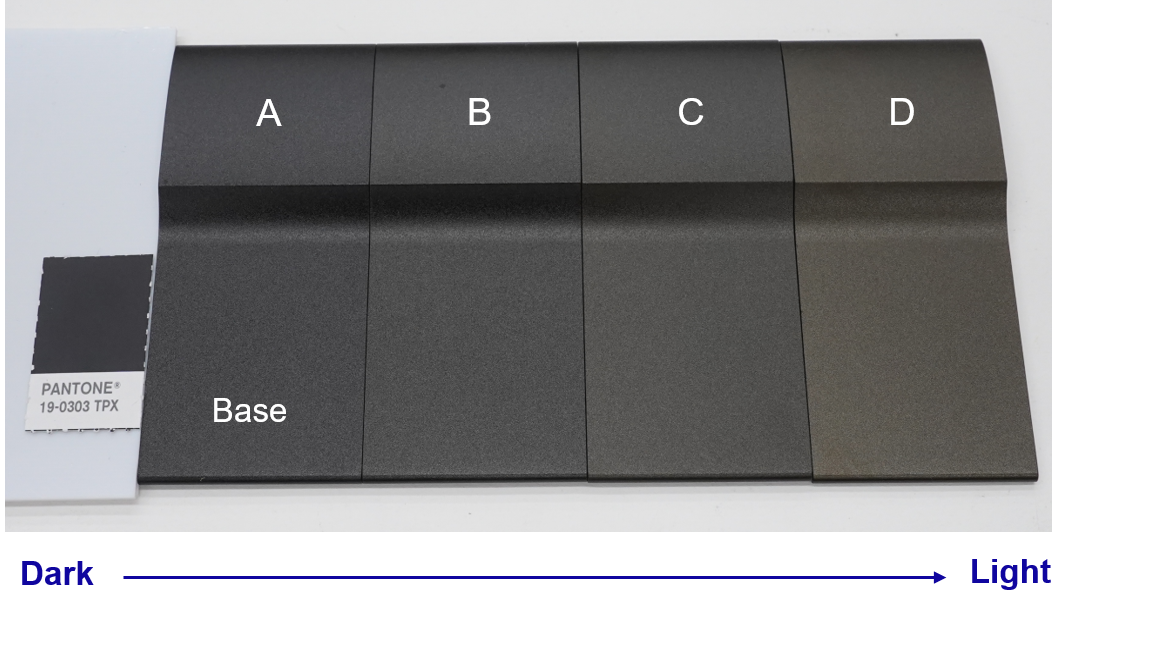

During the first round of testing, we provided our customer with four anodized color swatches for review. Their feedback indicated that swatches C and D leaned too green, but swatches A and B had the neutral tone they desired. Recognizing our customer's preference for a neutral , not warm-toned, black, we set out to develop a shade darker than swatch A, without the use of warm dyes.

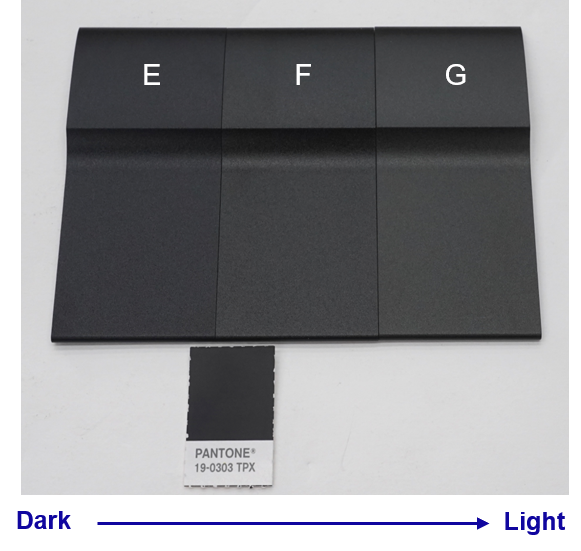

After fine-tuning, we developed three new shades of anodized colors with a more neutral tone. The target Pantone color sits between the darkest (E) and the second darkest (F) shades. Due to inherent impurities in dyes, absolute neutrality is not possible. Nevertheless, we will work closely with our customer to achieve the closest possible match to a neutral color.

Side story:

Our customer's existing product line is exclusively silver, and they wanted to maintain a consistent brand image. However, to give their new products a fresh look, they were considering introducing a new dark silver color. Depending on the material, some will be painted, while others will be anodized. During the development of the new dark silver color, our customer encountered a challenge when realizing that the final product could only be painted, not anodized. This posed a dilemma for our customer, prompting them to consider whether to continue developing the anodized color or start over and switch to developing a traditional paint color.

Generally, adjusting an anodized color is much more challenging than adjusting a traditional paint color. However, once the anodized color swatch is completed, it becomes significantly easier to either replicate the same anodized color or match it to a traditional paint color. Therefore, we recommended our customer to press on with developing the anodized color in this case.

Stay tuned for Part II.